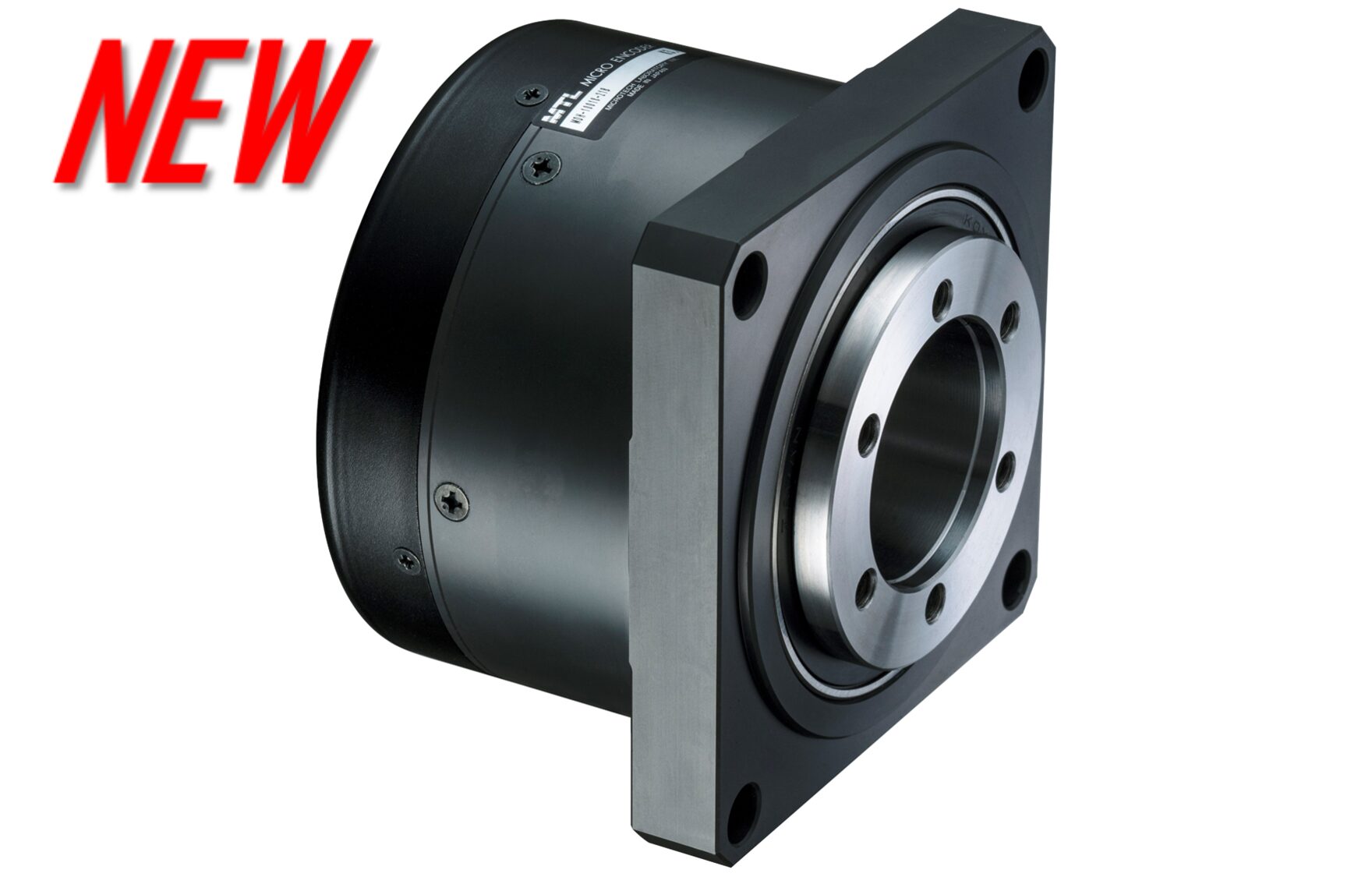

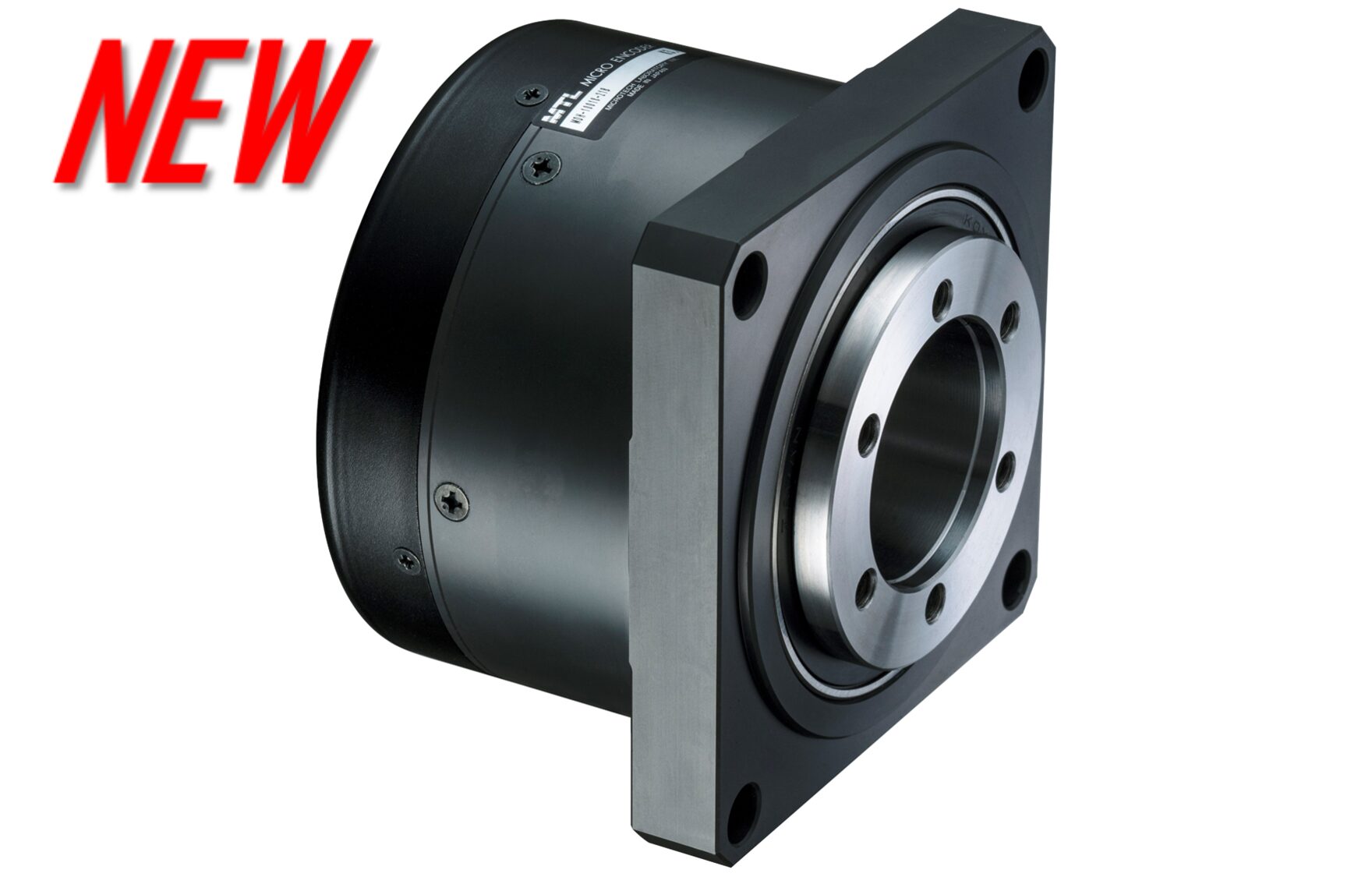

MDH-100 Series

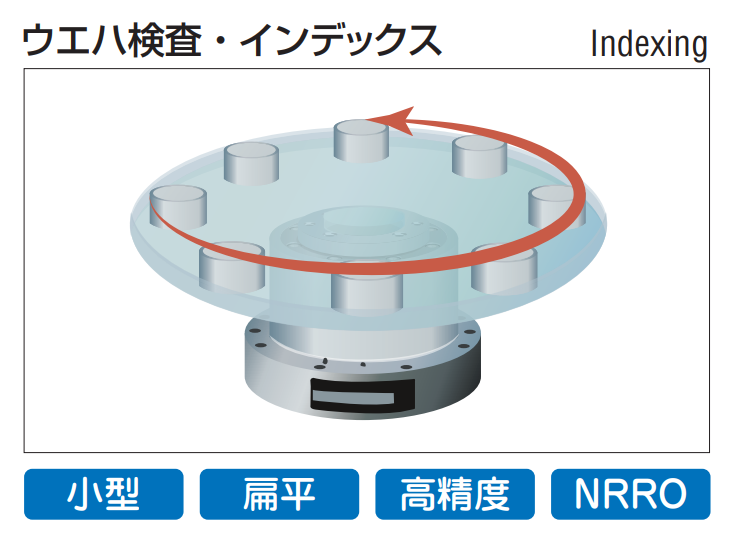

Introducing OD φ100 in the μDD lineup. This is the highest torque series with a peak torque of 9.6 Nm.

Contact

Contact

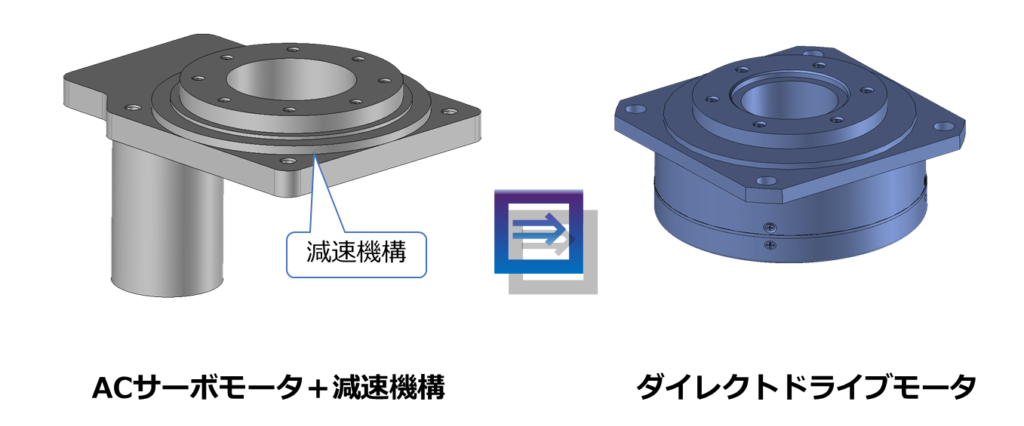

A direct drive motor (DD motor) drives the load directly without a gearbox, belt, or pulley.

Because the drivetrain is simple, you eliminate backlash and wear, and you can achieve quiet operation, long service life, and highly repeatable positioning.

DD motors also deliver high torque at low speed, which is why they are widely used in industrial robots, inspection and metrology systems, semiconductor equipment, medical devices, and other precision automation.

Microtech Laboratory’s μDD Motor combines compact size, high torque, and a high-resolution integrated encoder, helping machine builders reduce footprint and weight while improving positioning performance.

Gearless drive means the motor rotates the load directly without any reduction gears.

With no gear wear and no backlash, you get smooth motion and precise positioning.

Fewer mechanical parts also supports a lighter, more compact machine design, quieter operation, and reduced maintenance.

These benefits make gearless direct drive ideal for precision motion systems and robotics.

Backdrivability is the ability for the output shaft to rotate smoothly when an external force is applied.

In geared systems, friction and reduction mechanisms often resist motion, making it harder to achieve compliant, natural behavior.

Backdrivable direct drive systems respond cleanly to external forces, which is beneficial for force interaction, haptic feedback, and safer collaboration with people.

With no gearbox, there is no backlash. This supports stable, repeatable positioning for precision axes.

Eliminating belts and reducers reduces parts count and helps shrink the overall mechanism.

Fewer mechanical interfaces means less friction noise and smoother rotation at low speed.

With fewer wear components, maintenance intervals and downtime can be reduced.

High backdrivability can be beneficial for collaborative systems and force interaction.

Hollow-shaft designs allow cables, air tubes, or optics to pass through the motor, simplifying integration.

No gear mesh noise improves the working environment and makes abnormal sounds easier to detect.

Backlash-free transmission improves the accuracy and repeatability of the drive axis.

Fewer parts can reduce the overall mechanism size and free up valuable space.

With fewer mechanical losses and less compliance, available torque can be used efficiently for acceleration and deceleration.

A beneficial characteristic for master-slave control and haptic/force-feedback systems.

Learn about master-slave control ➡︎

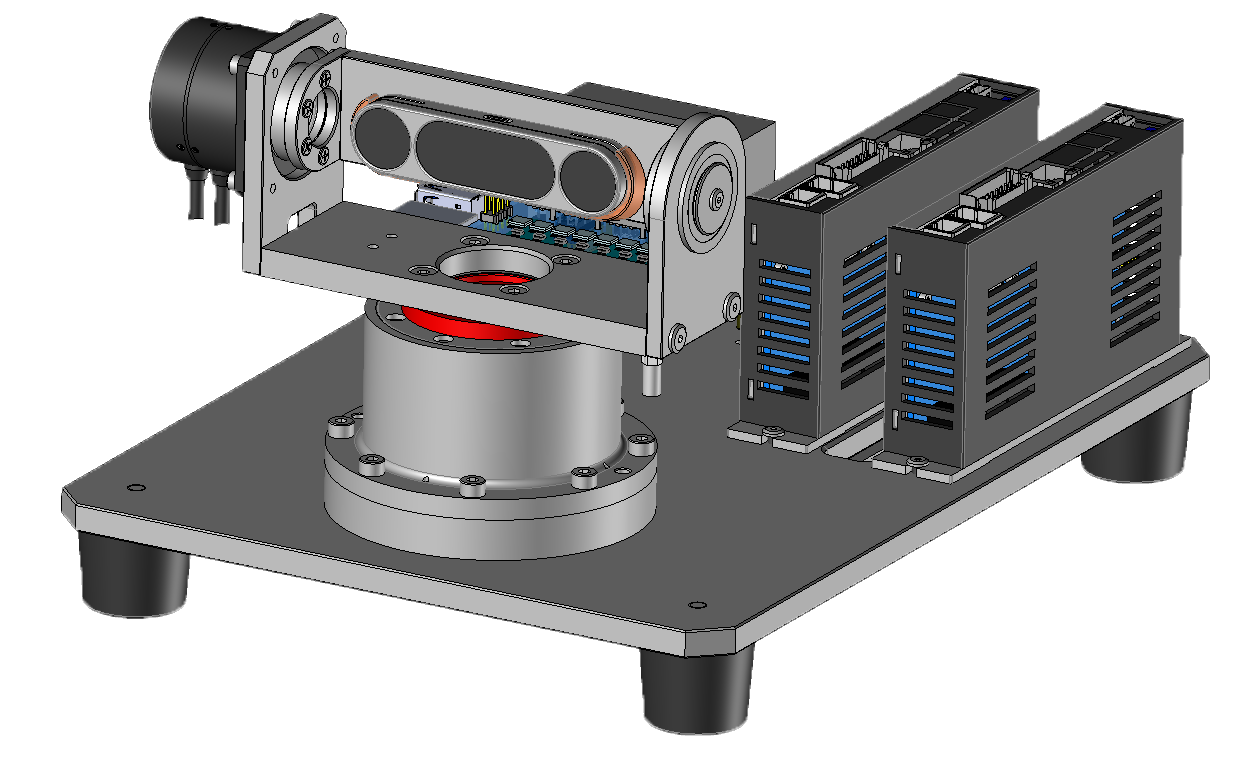

Introducing OD φ100 in the μDD lineup. This is the highest torque series with a peak torque of 9.6 Nm.

Compact, large hollow shaft. Ideal for index tables, rotary actuators, and robot joints (elbow/shoulder class).

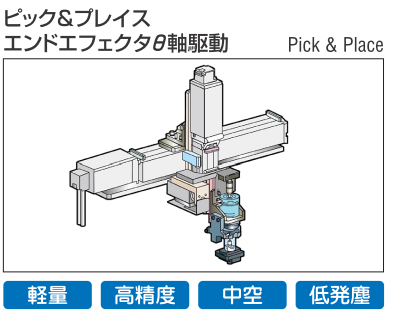

Compact, large hollow shaft. Great for end effectors and robot joints.

Enlarged inner diameter version of the MDH-40 series. A φ12 mm bore allows routing cables, laser optics, and more.

Ideal for end effectors (transfer θ axis, alignment), production automation, and robot joints (wrist class).

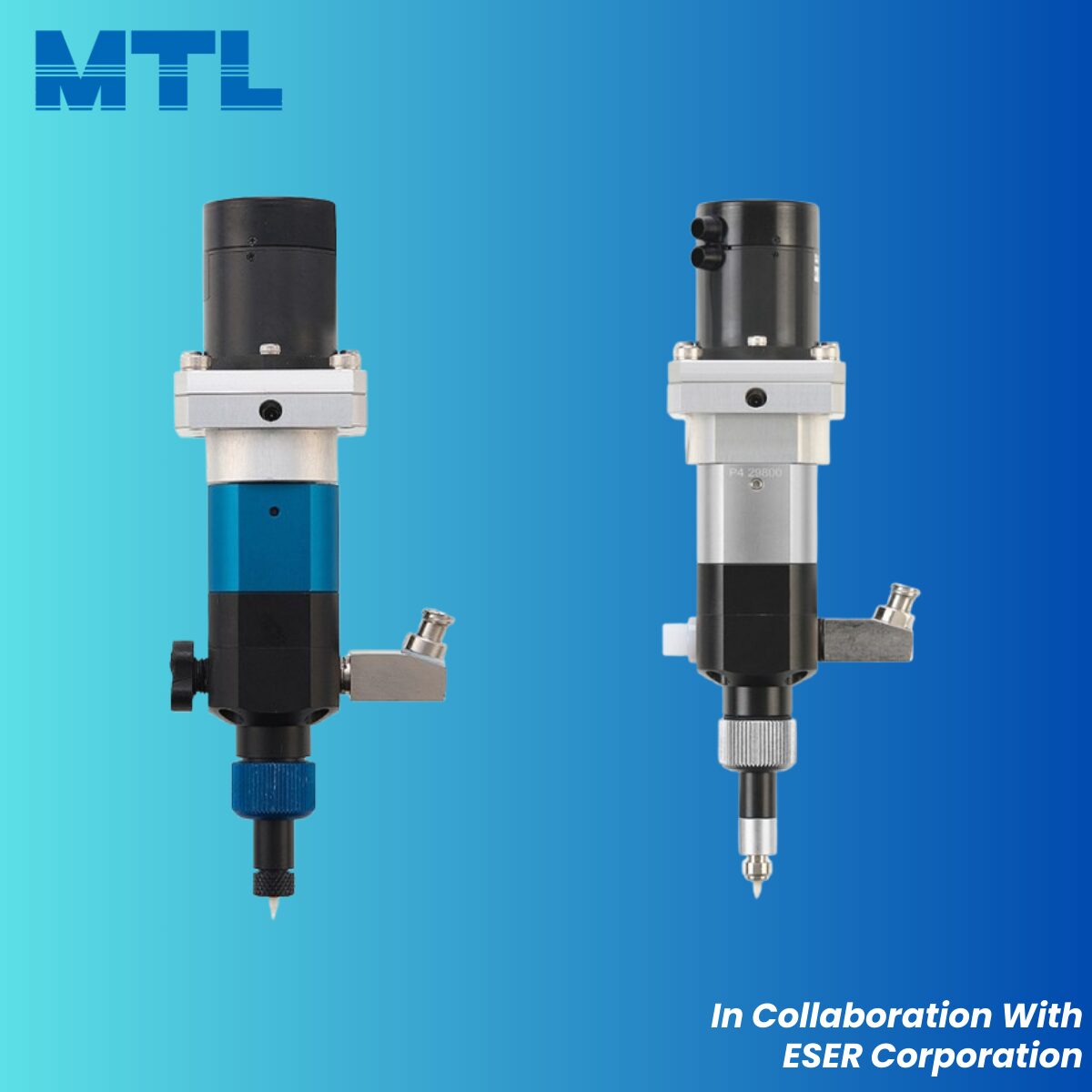

Ideal for high-precision dispensing and compact gimbal axes. A tapped hollow shaft can support rotary joints for air tube routing.

World’s smallest-class through-bore servo motor. Ideal for end effectors (hands, grippers, Zθ units). Can also be paired with low reduction gears for compact hands.

The world’s smallest direct drive motor. Ideal for grippers and robot hands handling lightweight workpieces such as electronic components.

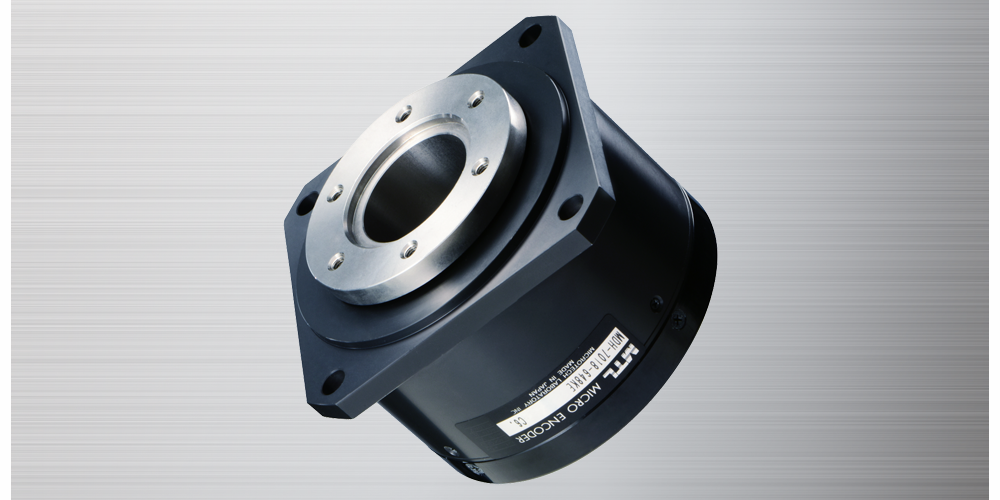

The μDD Motor (Micro Direct Drive Motor) is Microtech Laboratory’s original compact direct drive servo motor developed for high-precision motion in tight spaces.

Because it uses a gearless direct drive architecture, it avoids backlash and wear and delivers smooth, highly repeatable motion.

The design provides strong torque at low speed, and the high-resolution encoder is integrated into the motor, enabling accurate position feedback for precision control.

With a hollow-shaft structure, cables, air tubes, and optics can pass through the motor, simplifying mechanical layout and improving design freedom for compact machines.

μDD Motors help solve integration constraints that are difficult to address with conventional gear-driven actuators and support next-generation motion control for semiconductor equipment, inspection systems, robotics, and more.

Reduce three common losses on the shop floor

Case Studies

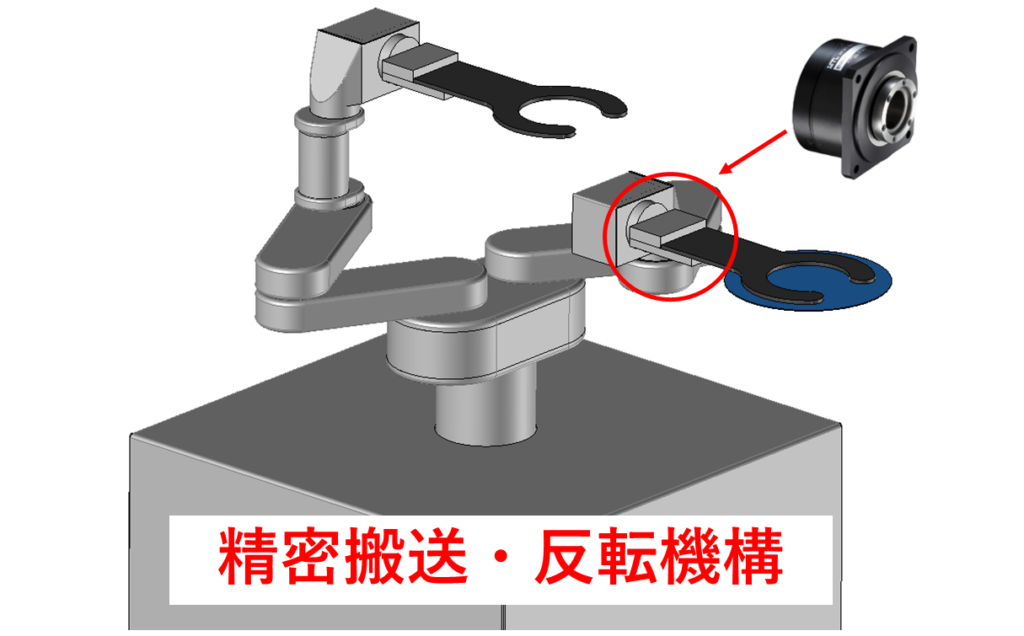

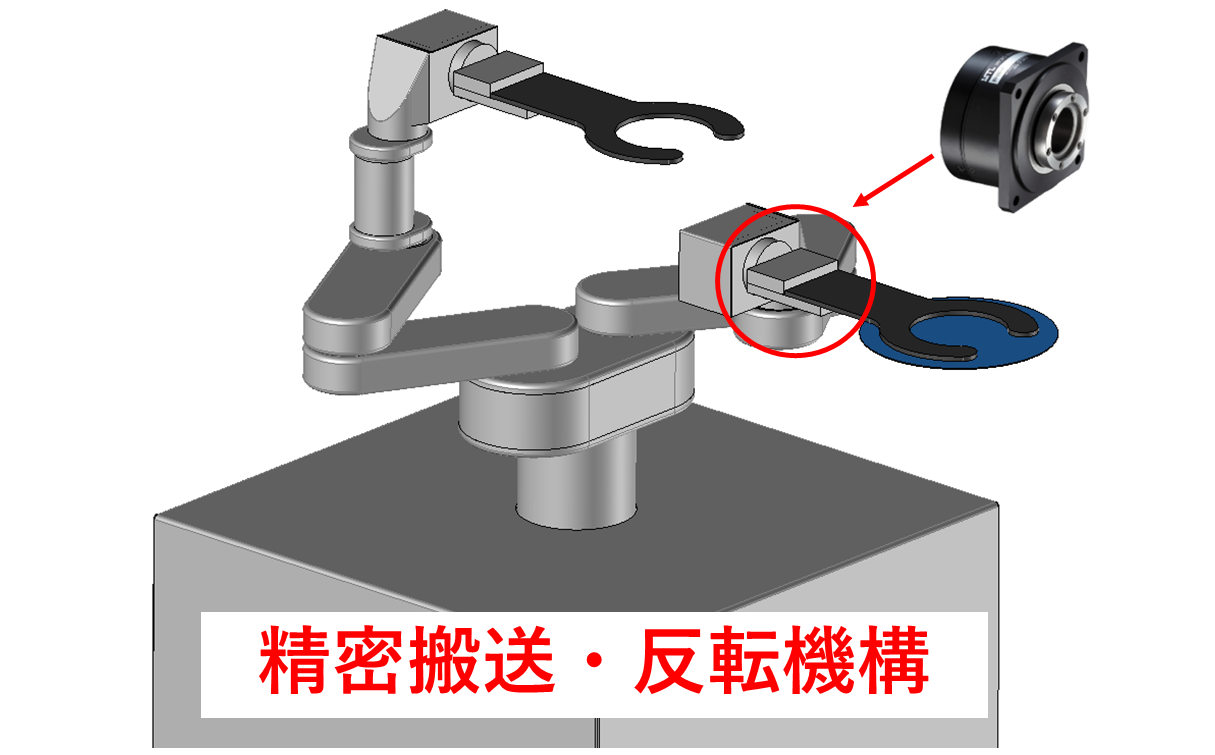

Gearless direct drive eliminates backlash and reduces vibration, helping flip delicate wafers smoothly and reliably. The compact structure also supports a lighter mechanism and space savings, improving stability and throughput in semiconductor handling.

Customization example

We added an M5 × 0.8 tap inside the hollow shaft of the MDH-30 series.

This allows direct mounting of a rotary joint for clean air-tube routing through the axis.

Compact, lightweight, high precision

Often adopted in back-end processes. Hollow-shaft integration and customization help solve tight packaging constraints.

Download the brochure

Precise rotary motion in limited space. Adopted in compact testing and automation instruments.

Ideal for coaxial laser attenuators and high-precision pan-tilt gimbal axes where a hollow-shaft motor helps with clean routing.

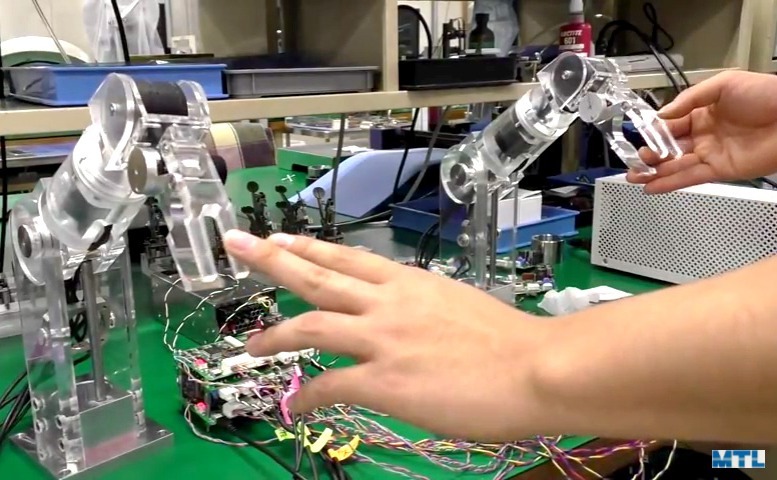

Compact high torque supports smaller robots. Large hollow bores also simplify cable routing through joints.

Backdrivability is valued for control schemes involving haptic feedback and force interaction.

| Item | Stepper motor | AC servo motor | Direct drive motor | μDD Motor |

|---|---|---|---|---|

| Repeatability | Good | Good | Excellent | Excellent |

| Absolute accuracy | – | Good | Good | Excellent |

| Heat generation | Fair | Fair | Good | Excellent |

| Stiffness | Fair | Good | Excellent | Excellent |

| Hollow shaft | Good | Good | Excellent | Excellent |

| Size | Excellent | Good | Fair | Excellent |

| Torque (gearless) | Good | Good | Excellent | Excellent |

| Best speed range | Mid to high | Mid to high | Low to mid | Low to mid |

| Low-speed speed ripple | Poor | Fair | Excellent | Excellent |

| Backdrivability | Poor | Fair | Excellent | Excellent |

| Typical configuration | Gear or belt | Gear or belt | Direct drive | Direct drive |

| Cost | Low | Mid | High | High |

| Best-fit examples | High-speed rotation | General positioning | Precision rotation (larger) | Precision rotation (compact) |

Note: This is a general reference. Actual performance depends on your load, stiffness, tuning, and thermal conditions.

When you contact us, a dedicated engineer will support your motor and driver selection.

Please reach out via this form.

Our products are managed under a strict quality assurance system after passing extensive validation tests.

In the unlikely event of initial defects, we will replace the unit at no charge.

After-sales support includes repair services and root-cause analysis for abnormal behavior.

• Tuning support

・Auto-tuning function

Setup steps and measured performance are available here (released in 2024).

・Manual tuning for further optimization

Tuning recipes and procedures are available here (user registration required).

Paid tuning support by MTL engineers: contact us.

・You can also use a third-party servo driver.

Compatible driver brands are listed here.

These are the questions we see most often when engineers switch from geared or belt-driven rotary axes to direct drive. If you share your duty cycle and load profile, we can confirm sizing and integration quickly.

A μDD Motor is a compact direct drive servo motor with an integrated high-resolution encoder. The motor is a three-phase permanent magnet design intended for smooth position, velocity, and torque control.

ASend any of the items below. Even partial data is okay, we can estimate the rest.

Practical tip: if your issue is low-speed ripple or settling, a short video of the behavior helps.

A Direct drive sizing is usually based on your torque profile over time: acceleration torque (inertia × angular acceleration) plus steady torque (friction and process load).

A Inertia ratio strongly affects control stability and settling. If the reflected load inertia is far larger than the motor rotor inertia, the servo may require more careful tuning and can show overshoot, hunting, or low-speed ripple depending on stiffness and feedback resolution.

Practical actions if you see issues:

A Often, yes. Geared and belt systems can add compliance, friction, and backlash effects that show up as ripple at low speed. A direct drive axis simplifies the drivetrain and can improve low-speed smoothness, especially for inspection rotation, alignment, and indexing.

A Yes. This is a common reason to choose a hollow-shaft direct drive motor. It helps reduce interference, simplifies assembly, and keeps the axis clean.

A It depends on your load path. Many direct drive integrations use a dedicated bearing set to handle radial and axial loads, while the motor provides torque and feedback.

A Direct drive systems are generally backdrivable, so holding behavior depends on your mechanism. If you need position holding during power-off, plan a brake or mechanical lock, or design a safe resting position.

Safety note: for vertical or gravity-affected mechanisms, always define a fail-safe strategy.

A Heat is mainly driven by duty cycle and continuous torque. Mechanical mounting matters because the motor body often serves as the heat path.

A In many cases, yes, if required torque, speed, and footprint allow it. A direct drive approach removes backlash sources and reduces wear parts, but it shifts more responsibility to sizing, stiffness, and tuning.

If you send your current motor, gear ratio, output torque, speed range, and axis dimensions, we can propose a compact direct drive option.

A We offer MTL driver options and also support third-party servo drives depending on the encoder interface and control requirements. Please refer to our compatibility list and contact us if you are unsure.

A Here is a practical checklist we recommend during concept design:

Microtech Laboratory Co., Ltd. has been a specialist manufacturer of compact, high-precision rotary encoders and direct drive motors since its establishment in 1981.

Headquartered in Sagamihara, Kanagawa, we supply products to a wide range of industries including precision instruments, robotics, and semiconductor manufacturing equipment.

Our strength is proprietary engineering that delivers high performance in compact form factors. The μDD Motor integrates a high-resolution encoder and uses a gearless direct drive design to support precision control with low noise. With hollow-shaft options and flexible customization (even from one unit), we help machine builders solve integration constraints and accelerate development.

| Company name | Microtech Laboratory Co., Ltd. |

|---|---|

| Established | February 1, 1981 |

| Capital | JPY 45.5 million |

| President & CEO | Yusuke Nomura |

| Business | Design, manufacturing, and sales of rotary encoders “Micro Encoder” and direct drive motors “μDD Motor” |

| Fiscal year end | July 31 |

| Head office | 8-1-46 Kamitsuruma-honcho, Minami-ku, Sagamihara, Kanagawa 252-0318, Japan |

| Contact | TEL: +81-42-746-0123 (main) FAX: +81-42-746-0960 |

| Main banks | Yokohama Bank, Sagami-ono Branch Mitsubishi UFJ Bank, Machida Branch Mizuho Bank, Machida Branch |

| Main customers | IHI Corporation / IHI Logistics & Machinery / Okubo Gear Industry / Shotek / JEOL / Hitachi High-Tech Science / Ono Sokki / Olympus / Harmonic Drive Systems / Canon / FUJIFILM / Sony / Honda R&D / Toshiba / Panasonic / Toyota Motor / Makino Milling Machine / Mitutoyo / Nikon / Moriya Transport Machinery / Yuyama / SANYO DENKI / and others |