Connecting to the future through Manufacturing

Building Manufacturing That Connects the Future

We aim to create manufacturing that works in harmony with the global environment.

By combining innovative technology with sustainable materials, we help optimize resources, reduce waste, and support a more sustainable society.

Our mission is to build a better future for the next generation through the products we deliver.

Less Waste, More Value

We work to minimize waste generated during production.

Through precise design and efficient use of resources, we are building an environmentally responsible production system.

We will continue to reduce environmental impact while delivering products that create real value.

MTL’s Initiatives

To reduce waste, MTL may ship products with minor cosmetic marks, only when they do not affect performance.

Reducing Scrap Rate

We are reviewing the criteria for certain parts (such as housings) that were previously discarded due to small cosmetic marks that do not affect product performance.

Because a certain amount of scrap occurs throughout the year, this effort is expected to reduce total waste.

From a sustainability perspective, by appropriately revising standards for areas that do not impact function, we will achieve both effective use of resources and reduced environmental burden.

100% Inspection During Production

To deliver high-quality products, MTL performs 100% inspection on all products during production.

We verify that every unit meets specifications, and we ship only those that meet our quality standards.

This allows us to supply reliable products consistently and earn customer trust.

Warranty

Our products are managed under a strict quality assurance system and pass multiple tests. If a defect occurs, we will support you with a free replacement.

Warranty period: 1 year after start of use (within 1.5 years after delivery) or 2,000 operating hours, whichever comes first. Warranty coverage: If a failure occurs due to our responsibility within the above period, we will repair or replace the product free of charge.

This warranty covers the delivered unit only. Costs related to replacement work and any consequential damages are not covered by MTL.

Cosmetic Mark Acceptance Criteria

1) Case marks

Light scratches on the exterior case do not prevent the product from performing its function.

However, dents or deep impacts may contact internal parts or cables and could cause a short circuit, so such parts are not used.

2) Base marks

Light scratches on the exterior do not prevent the product from performing its function.

We also set criteria for small cavities (porosity) that can occur during the base-part manufacturing process. Items larger than our 기준 are not used.

3) Cable marks

Surface scuffing on cables is acceptable.

However, cuts or sharp bends are not acceptable because they may cause wire breakage or short circuits.

For other parts built inside the product, we do not use items that may negatively affect product function.

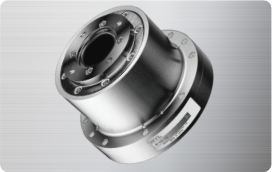

FAQ, Cosmetic Marks on μDD Motors

Q1. How can you judge whether a mark does not affect performance?

MTL performs 100% inspection during production, including torque, resolution, and electrical checks such as short detection. We ship only units that pass all tests. Based on these inspection results and our acceptance criteria, we can determine whether a mark is cosmetic only.

Q2. I scratched the product after purchase. Can I continue using it?

If it is a minor scratch or scuff from light contact, it is generally fine to continue using the product.

If the unit was dropped, or you can see a dent or a strong impact mark, internal parts may have been damaged. If you are unsure, please contact us. We can perform the same inspection as our shipment test through our inquiry form.