Contact

Contact

エンコーダとは

What Is a Rotary Encoder

MTLの

ロータリエンコーダとは

A rotary encoder is an electronic component that converts rotational or linear motion into signals used to detect direction, displacement, and angle.

Rotary encoders are used with motors and in many other applications. MTL encoders are integrated into a wide range of equipment and systems across industries.

ご利用場所

From everyday equipment to specialized systems.

-

Elevator speed control and floor leveling

-

Roller speed control in industrial printers

-

Integration with ultra-compact industrial actuators

-

Broadcast camera systems

エンコーダの種類

Used across general and advanced applications.

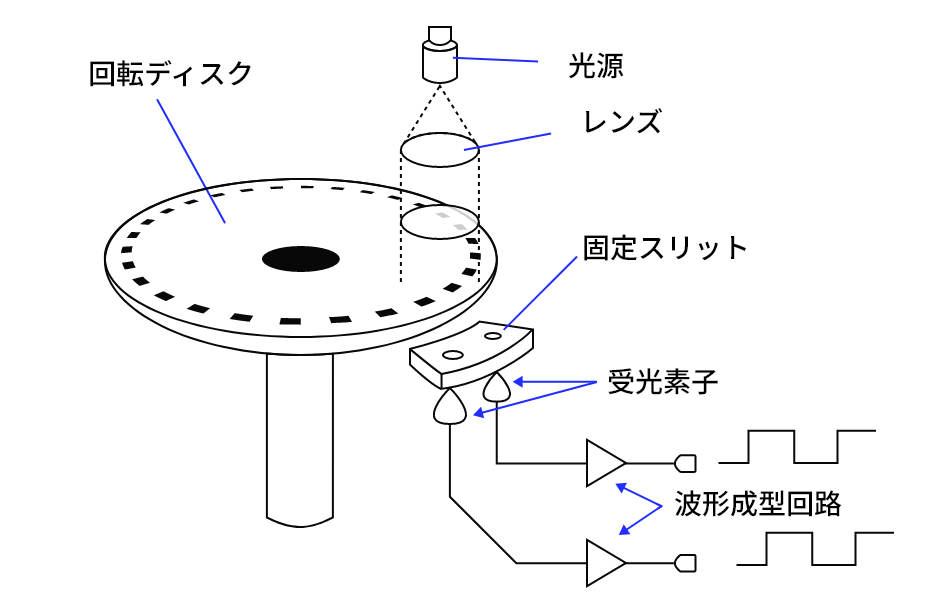

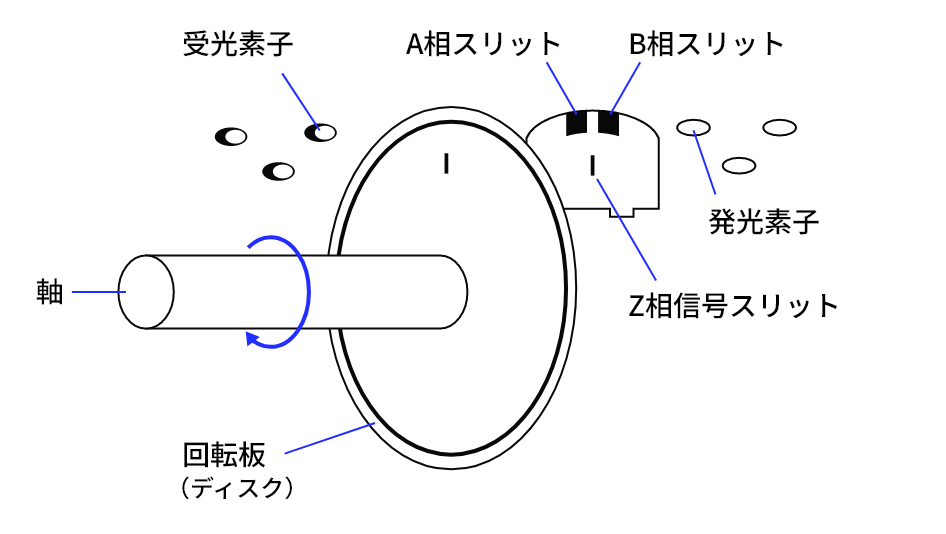

インクリメンタル方式

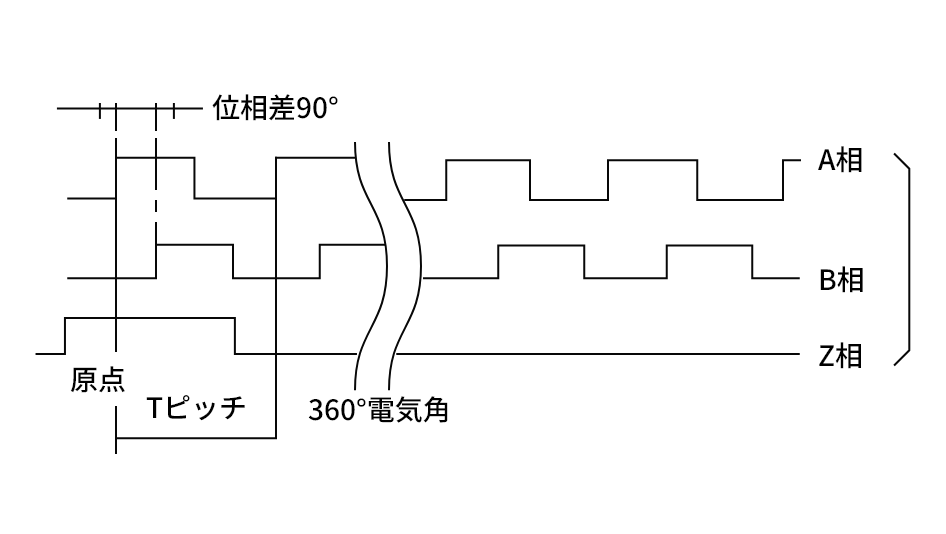

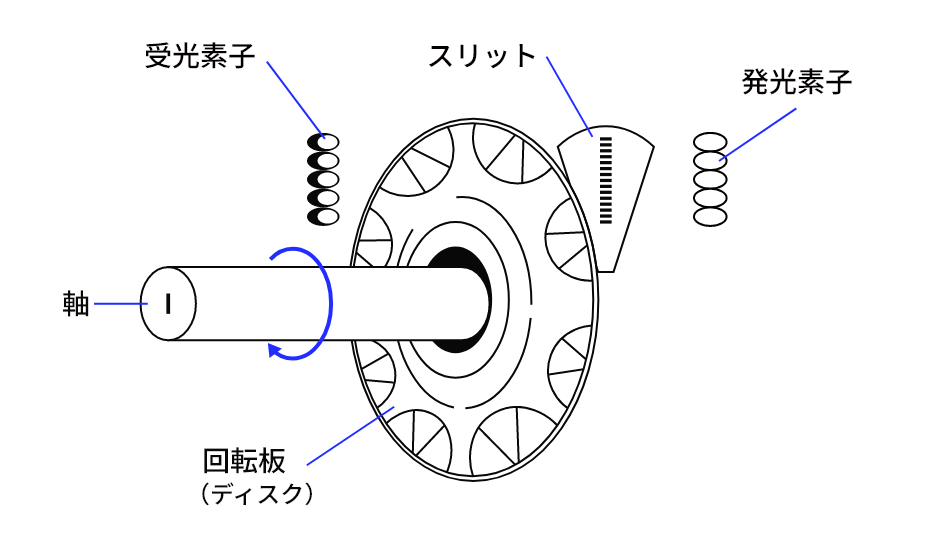

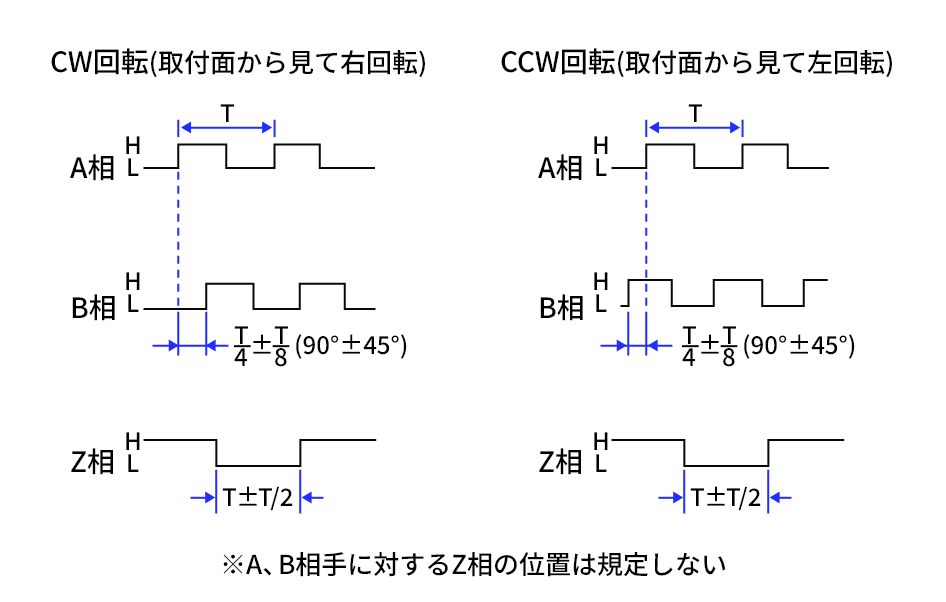

Incremental encoders use a disk with evenly spaced slits. Two photo-detectors output phase-shifted signals (A and B). A counter calculates rotation by adding or subtracting counts based on the direction derived from A/B phase. If pulses are missed or miscounted, the resulting error remains until an index or reference is applied.

構造

出力波形

アブソリュート方式

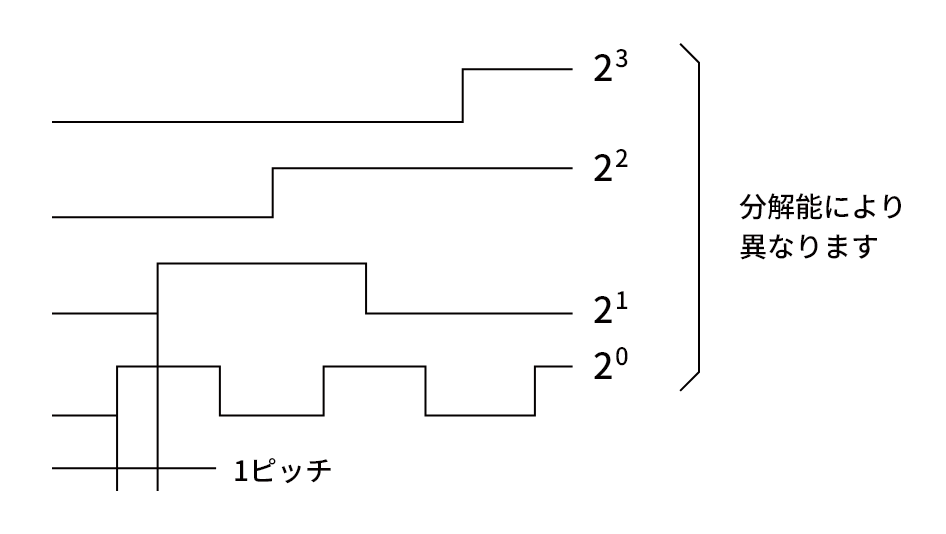

Absolute encoders assign a unique code pattern to each position on the disk and output an absolute angular position independent of motion history. They’re robust against noise, but achieving higher resolution generally requires more bits (signal lines). Coding schemes include binary and Gray code.

Binary code can switch multiple bits at boundary transitions, increasing the chance of read errors. Gray code changes only one bit between adjacent positions, so a single-bit misread results at most in an adjacent position error. For this reason, Gray code is commonly used in absolute rotary encoders.

構造

出力波形

CONTACT

Request a product demo or a quotation. Feel free to contact us.

インクリメンタルタイプの出力回路と出力波形について

Used across general and advanced applications.

Supply Voltage: DC 5–12 V or Fixed 5 V/12 V

Supply Voltage: DC 5–12 V or Fixed 24 V

Supply Voltage: DC 5 V, Current Consumption ≤150 mA

*For long transmission distances, ensure the input end of the encoder cable receives the specified voltage.

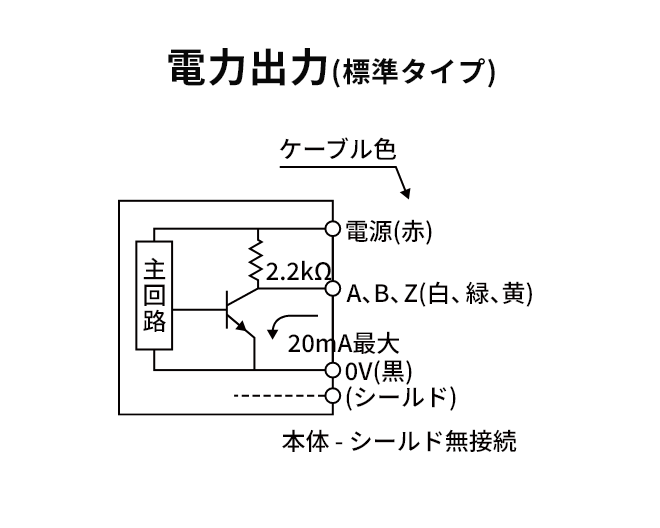

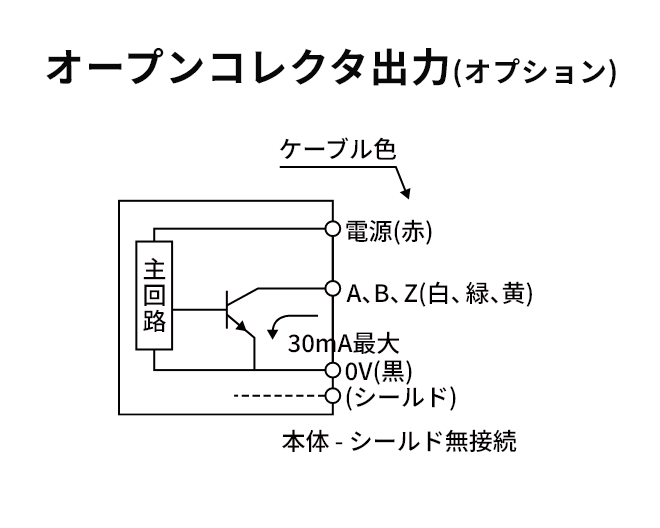

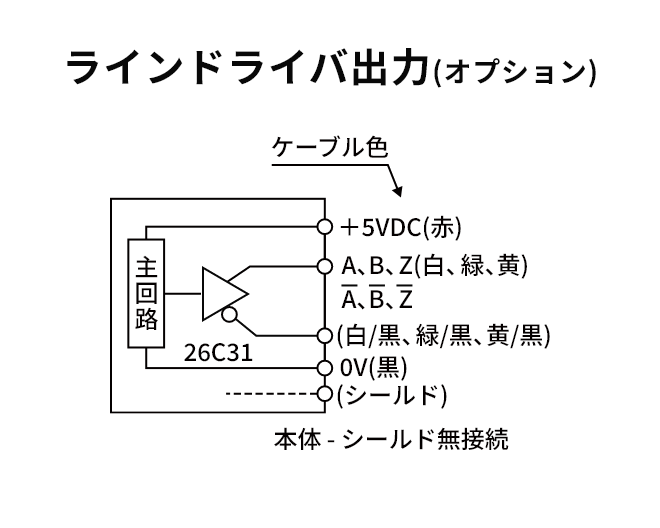

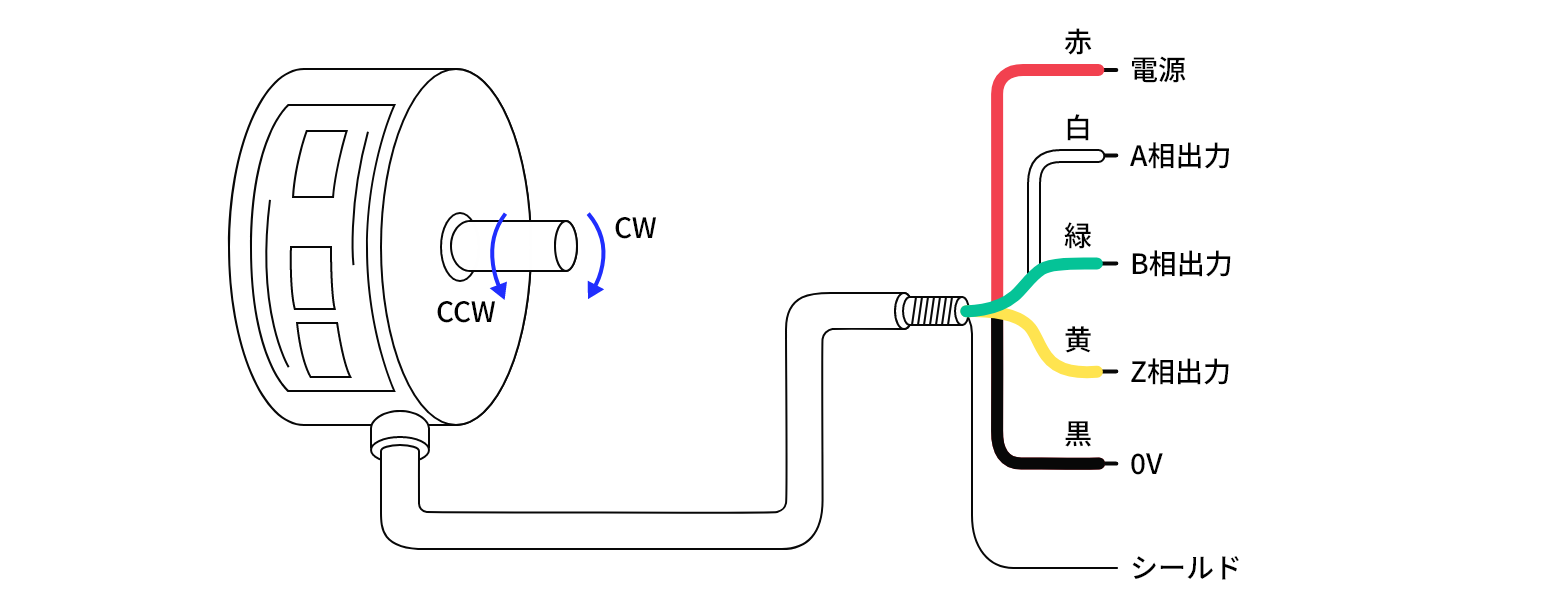

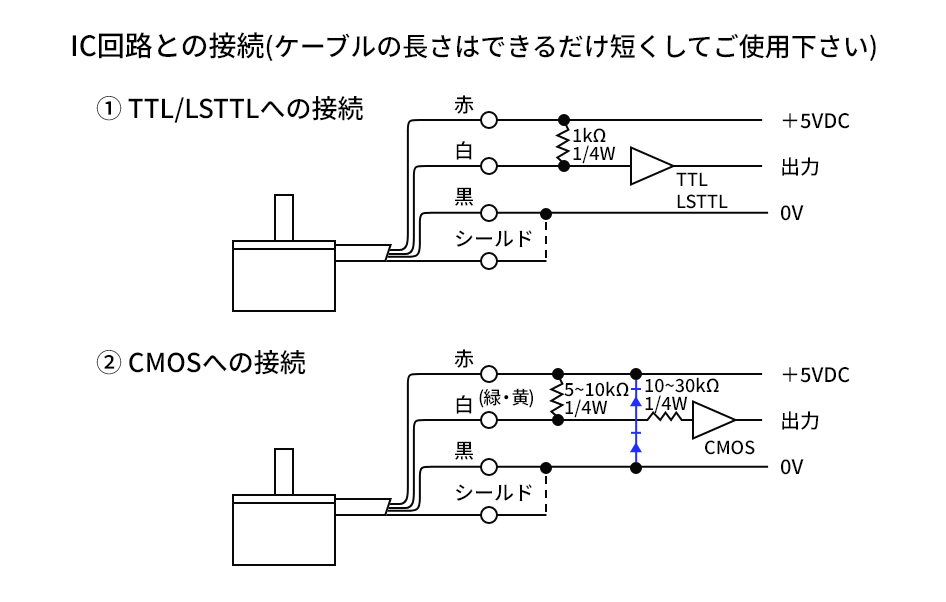

Output Circuit Diagram

Connection Example

長くお使いいただくために

The LED light source typically defines encoder service life (about 10 years). External conditions may shorten life or cause failures.

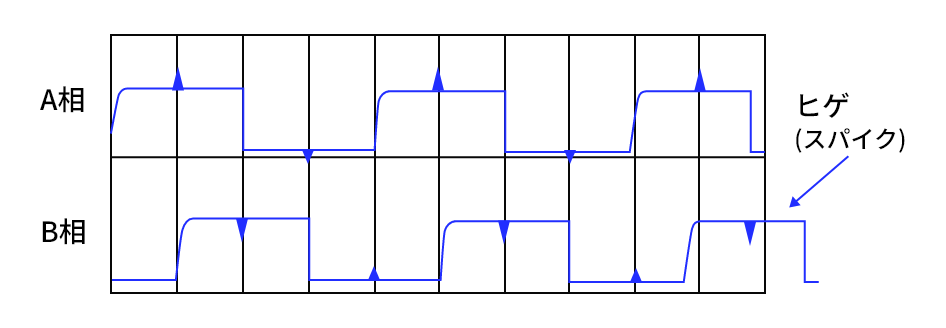

On rectangular (TTL/CMOS) outputs, small “spikes” may appear on the flat parts of the waveform depending on cable length. This results from stray capacitance between signal lines—switching on A or B induces a transient on the other line.

For example, when A is high, the rising edge of B can cause a transient above A’s high level; when A is low, the falling edge of B can cause a transient below A’s low level. If these transients remain outside the system’s logic thresholds, they are not an issue.

Counting typically increments when A=H then B=H. Brief chatter on A alone does not increment counts. To reduce spikes, use a smaller load resistance, shorten the cable, choose low-capacitance cable, and connect the cable shield to 0 V to help suppress noise.

For better noise immunity, connect the encoder cable shield to FG (earth). We also recommend grounding the customer-side PCB to FG, unless FG is a noise source in your system.

Common Causes of Failure

01

Reverse Polarity (Vcc/GND)

Wiring mistakes or incorrect connector mating can reverse power polarity. Please have qualified personnel perform connections.

02

Overvoltage

Use a regulated power supply within the specified range. Route wiring to minimize noise coupling from other equipment.

03

ESD / Surge Noise

Our ESD countermeasures include:

- Antistatic workwear

- Antistatic footwear

- ESD-grounded mats on workbenches

- ESD panels at factory entrances

- ESD wrist straps

- Use of ionizers

04

Shorts Between Signal Lines

Shorts can prevent proper pulse detection. This often occurs with unused or floating wires. Please check all cable terminations carefully.

In Case of Malfunction

We can investigate defective products to determine the cause and whether repair is possible.

Please feel free to contact us for more details.