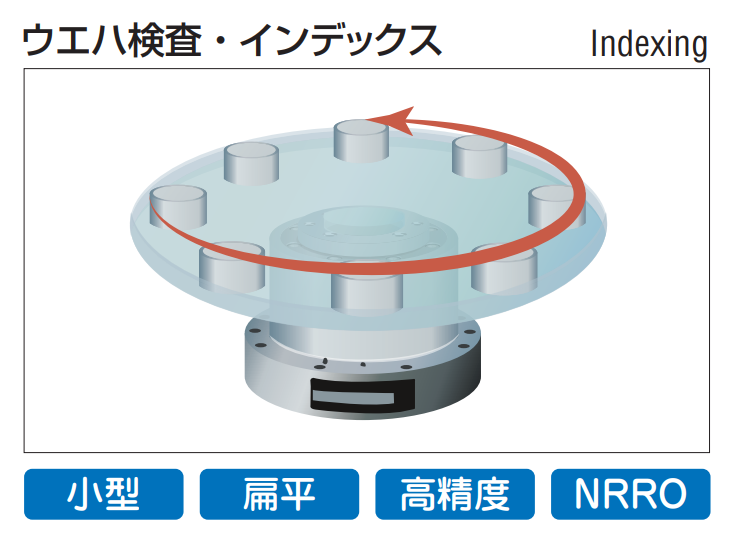

Wafer Inspection Index Mechanism

This example covers a rotary index axis used in wafer inspection and inspection tables. The focus is stable rotation, low runout, and low vibration.

Applications: wafer inspection, inspection tables, index rotation.

Challenge: runout on the axis and mounting surface, vibration during motion

When inspecting wafer warpage or detecting dust on the wafer surface, the actuator and mechanical structure can become a bottleneck.

If the axis runout is high, it affects roundness measurement. If the mounting surface has runout or distortion, it affects warpage measurement.

Vibration caused by tolerances and mounting errors can also affect inspection results.

1) μDD motor benefits

- High accuracy and stable rotation

Even in space-limited setups, the system achieves ≤ 5 μm face runout and ≤ 1 μm NRRO (Non-Repeatable Run-Out). - Low vibration and durability

The direct drive structure reduces vibration and maintains accuracy over long operation. - Hollow shaft for more functions

Routing air tubes and cables through the hollow shaft supports a wide range of uses, including wafer handling and slurry supply. - Stable settling with high inertia loads

Stable settling motion even with inertia ratios over 1,000×.

2) Main motors used

| Model name | Product name | Remarks | |

| 1 | MRS-7056-648KE | Compact large-bore hollow rotary actuator | Base outer diameter: φ90 mm, hollow bore: φ25 mm Resolution: 259,200,000 counts/rev Peak torque: 3.1 Nm |

| 2 | MDH-10018-21B | Large-bore hollow direct drive motor | Outer diameter: φ100 mm, hollow bore: φ40 mm Resolution: 2,097,152 counts/rev (21-bit) Peak torque: 9.6 Nm |

| 3 | MRS-100 | Compact large-bore hollow direct drive motor | In development |

Notes

Runout and vibration depend on the whole system, including bearing support, base stiffness, and mounting accuracy. If you share your table size, speed profile, and inspection requirement, we can recommend a suitable motor and layout.

Contact

Send us your wafer size, table diameter, target rotation speed, and runout requirement. If you need tubing or cables through the hollow shaft, include the line size and routing plan. We will recommend a suitable μDD motor or actuator for your inspection index.