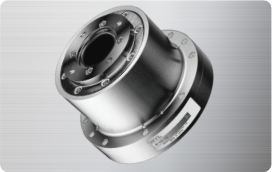

Pick-and-Place Θ Axis End Effector

This example shows a Θ (theta) rotation axis at the end effector for precision pick-and-place. It is designed for stable alignment and compact routing at the tool tip.

Applications: precision equipment such as die bonders, wire bonders, flip-chip bonders, mounters, and Θ-axis alignment modules.

Challenge: Issues caused by too many mechanical parts

Many conventional pick-and-place mechanisms use ball screws and belt drives for linear and rotary motion. This often creates backlash and play. Wear parts can also limit positioning accuracy and make acceleration and deceleration less stable.

Because these mechanisms require many joints and components, maintenance takes time. Routing cables and tubes can also become difficult, which restricts the design.

1) μDD motor benefits

- Lower moving mass

Reducing weight at the end effector lowers inertia and residual vibration. This supports higher acceleration on XYZ axes and helps shorten tact time. - High accuracy

Direct drive removes gears and belts.

This supports fine positioning and precise alignment work, which helps improve yield. - Compact routing

The hollow shaft allows air lines and tubes to pass through the axis for a space-saving layout.

This improves work efficiency in tight spaces and increases design freedom. - Lower maintenance

Reducing mechanical elements such as gears and belts supports a low-particle design.

This fits cleanroom environments, and fewer wear parts reduce regular maintenance workload.

2) Main motors used

| Model name | Product name | Remarks | |

| 1 | MDH-2018-36KE(tool tip) | Ultra-compact hollow-shaft direct drive motor | Outer diameter: φ21 mm, hollow bore: φ2.6 mm Resolution: 144,000 counts/rev Peak torque: 130 mNm |

| 2 | MDH(12)-4018-324KE(middle) | Compact large-bore hollow-shaft direct drive motor | Outer diameter: φ40 mm, hollow bore: φ12 mm Resolution: 1,296,000 counts/rev Peak torque: 1 Nm |

Notes

End-effector performance depends on the full structure, including stiffness, bearing support, and tuning. If you share your payload, tool mass, and target tact time, we can recommend a suitable motor set and layout.

Contact

Send us your required rotation range, payload, cycle time, and space limits. If you need air or tubing through the axis, include the line size and routing plan. We will recommend a suitable μDD motor for your Θ axis.