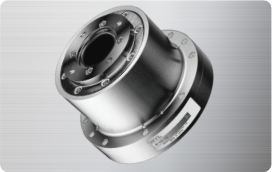

Compact High-Speed Screw Dispenser

This case shows a compact mechanical dispenser that uses a μDD motor. It keeps dispensing stable and repeatable while helping reduce the overall size of automation equipment.

Keeps dispensing accuracy and stability, while helping miniaturize automation equipment.

To solve the size constraint that many automated systems face, this mechanical dispenser integrates a latest μDD motor in a compact layout.

1) What is a screw dispenser

A screw dispenser (mechanical dispenser) delivers material with high repeatability. It is widely used in automation lines where stable dispensing matters for yield and rework control.

Ether Corporation Japan’s “AMD Series” supports precise material dispensing and efficient supply in semiconductor production and precision equipment assembly.

(2) uDD motor models used in AMD series (AMD3, AMD7, AMD8)

Wide fluid range

• Supports low to high viscosity materials with controlled dispensing

• Handles small-volume dispensing for materials such as anaerobic adhesives

• Built for continuous operation

Durability for long runs

• Stable dispensing performance during continuous operation, including high temperature and high viscosity conditions

Lower maintenance and operating cost

• Gearless structure reduces wear parts and maintenance work

• Uses durable zirconia ceramic screw for longer life

• Uses carbide or ceramic cylinder to reduce wear and keep operation stable

Eser Corporation Japan website

AMD series details

Contact Eser about the dispenser

(3) μDD motor role

Dispensing quality depends on stable rotation and repeatable control. A compact direct drive motor helps keep the mechanism small while maintaining steady screw motion. A gearless drive also reduces parts that wear over time.

(4) Motor used

| Model name | Product name | Remarks | |

| 1 | MDH-3006-108KE | Compact hollow-shaft direct drive motor |

Outer diameter: φ30 mm, hollow bore: φ4 mm Resolution: 432,000 counts/rev Max torque: 450 mNm Knurled shaft |

Reference

Contact

Send us the material type, viscosity range, target shot volume, and your space limits. We will recommend a suitable μDD motor for your screw dispenser and share integration notes.