Gearless μDD Motor Lifts a Hanging Weight

This demo lifts a hanging weight using a gearless μDD motor. It shows high torque in a compact size and stable motion during continuous up and down operation.

Compared to a same-size AC servo, this setup delivers about 5× torque.

Challenge

A compact lifting mechanism needs torque and stable motion. If the drive uses gears or belts, backlash and flex can make the motion less predictable, especially when the load direction changes.

This demo focuses on a simple requirement: lift and lower a hanging weight smoothly, quietly, and repeatedly.

μDD Motor Benefits

Direct drive removes belts and gears. This helps in two ways: it keeps the mechanism simple, and it reduces parts that add play or flex. In a small system, that makes motion easier to control.

| What the demo shows | What it means in a real machine |

|---|---|

| High torque in a compact size | More margin for lifting, clamping, and holding tasks. |

| Gearless motion | Fewer mechanical parts, simpler layout, and fewer wear points. |

| Stable motion under load | Better control when the load direction changes. |

Motor Selection

For small lifting or tension systems, these checks help you pick the motor quickly.

- Required torque: include peak torque for acceleration and margin for friction.

- Continuous duty: confirm heat and duty cycle if it runs all day.

- Radial load: confirm whether the axis takes load directly and check allowable radial load.

- Speed range: lifting speed and how smooth you need the motion to look.

- Mechanical layout: space limits and whether you need a hollow shaft.

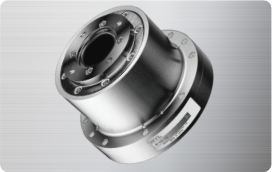

Motor Used

| Model name | Product name | Remarks | |

| 1 | MDH-2018-36KE(left) | Ultra-compact hollow-shaft direct drive motor |

Outer diameter: φ21 mm, hollow bore: φ2.6 mm Resolution: 144,000 counts/rev Allowable radial load: 44 N |

| 2 | MDH-4018-324KE(right) | Compact hollow-shaft direct drive motor |

Outer diameter: φ40 mm, hollow bore: φ6 mm Resolution: 1,296,000 counts/rev Allowable radial load: 140 N |

Integration Notes

- Support the load properly: decide where the load goes, motor bearing, external bearing, or both.

- Check radial load: if the axis takes load directly, confirm allowable radial load early.

- Keep the structure stiff: stiffness improves smooth motion and reduces vibration.

- Confirm duty: continuous motion needs a thermal check, not only peak torque.

Contact

Send us your load mass, lifting speed, stroke, and duty cycle. If you plan to apply load directly to the motor shaft, include the radial load and your bearing layout. We will recommend a suitable μDD motor and share integration notes.