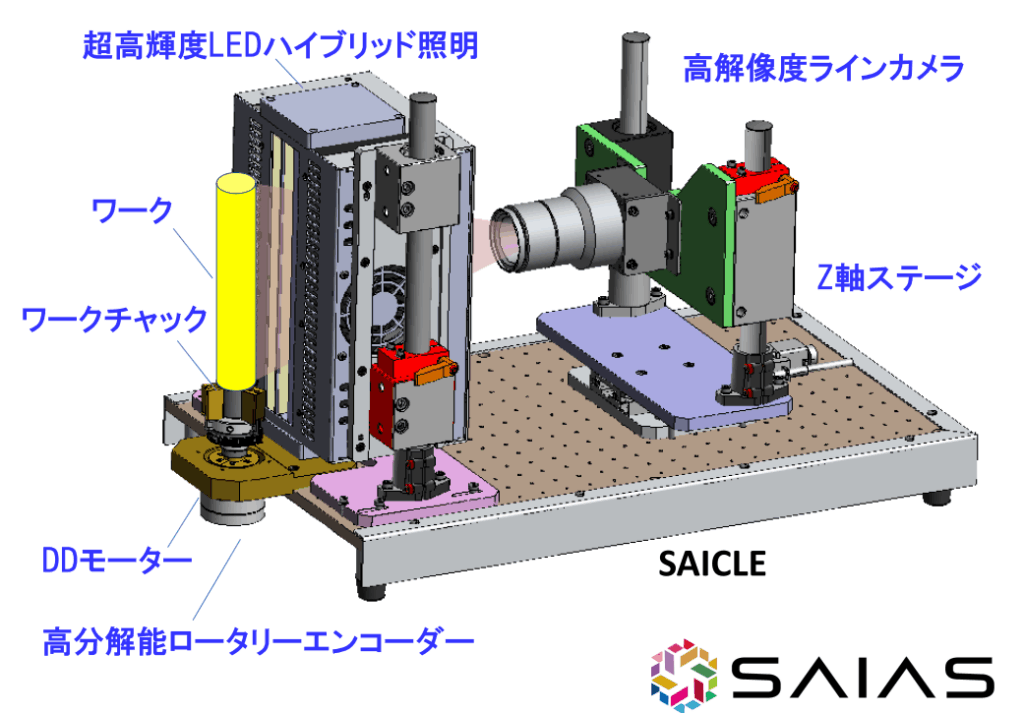

360° Surface Inspection for Cylindrical Parts

This system rotates a cylindrical workpiece and captures the full side surface in one pass. It targets fast inspection with stable image quality.

High-speed, high-accuracy inspection helps keep quality stable, even as throughput increases.

Challenge

To inspect cylindrical parts, the system must rotate the work smoothly and keep the camera image stable. If rotation speed changes or the axis does not run true, it shows up in the captured image and affects detection.

The goal is simple: rotate fast, keep runout low, and capture the full side surface in a short cycle time.

μDD Motor Benefits

Direct drive works well for inspection rotation because it removes belts and gears. This helps the axis rotate smoothly and repeatably, which supports stable imaging with a line-scan camera.

System Overview

• Rotates cylindrical workpieces 360° and captures the side surface with a high-resolution line-scan camera. The system can capture in as fast as 1 second (minimum).

• Uses high-brightness LED hybrid lighting with four lighting modes to handle different surface conditions. This improves detection sensitivity and reduces over-detection.

• Automatically sets the focus position based on work diameter.

• Uses inspection software that supports quick setup with a small number of samples.

Applications

1) Vision inspection systems using high-speed cameras

2) Laser 3D precision processing systems

3) Optical inspection equipment

User: SAIAS Co., Ltd.

Website: https://saias.co.jp/

System overview: https://saias.co.jp/system

Motor Selection

For 360° inspection rotation, these points decide the motor choice.

- Rotation time: how fast you need one full rotation, and how often it repeats.

- Image requirement: line rate and required surface resolution.

- Mechanical accuracy: runout, chuck accuracy, and bearing support.

- Work size: diameter range, mass, and how the part is held.

- Cable routing: whether you need a hollow shaft for wiring or air lines.

Motor Used

| Model name | Product name | Remarks | |

| 1 | MDH-6012-125KE | Compact hollow-shaft direct drive motor |

Outer diameter: φ60 mm, hollow bore: φ20 mm Resolution: 500,000 counts/rev Peak torque: 2.5 Nm |

Integration Notes

- Check runout first: work holding and bearing support often decide image stability.

- Match speed to the camera: set rotation speed based on line rate and target resolution.

- Use stiffness: a stiff mount and stable base reduce vibration during fast rotation.

- Validate with real images: confirm image stability at full speed, not only encoder logs.

Direct drive motors support high-speed, high-accuracy positioning stages.

Contact

Send us your work diameter range, target rotation time, and required image resolution. We will recommend a direct drive motor and share integration notes based on your setup.