Compact SCARA Robot for Direct Teaching

This demo shows a small SCARA built with μDD motors. The goal is simple operation, safe behavior, and a compact arm layout.

Using μDD motors, you can build a robot that is simple to use and safe, with a lower mechanical cost.

1) μDD motor benefits

- Repeatability: ±2 μm

Repeatability of ±2 μm supports tasks that need accurate motion, such as small-part assembly and precision inspection. It also supports stable motion in semiconductor and precision equipment production lines. - Compact arm layout with a gearless drive

A gearless structure keeps the arm compact. It also reduces friction and supports backdrivability, which allows manual arm adjustment (direct teaching). - Safe stop with external force detection

The robot includes a safety alarm that detects external force on the arm. If it detects a collision or overload, it outputs an alarm and turns servo off to stop safely. This helps in work areas where people and machines operate close to each other. - Low noise

Gearless design reduces sliding noise from gear mechanisms. This helps in quiet environments such as cleanrooms and labs. It also reduces noise issues when multiple robots run in the same area.

Motor selection

For a compact SCARA, motor selection usually starts from these points.

- Payload and reach: payload mass, arm length, and where the load sits.

- Cycle time: required acceleration and how fast the arm must settle.

- Hollow shaft need: wiring, air lines, or vacuum lines through the axis.

- Safety behavior: force detection thresholds and stop behavior.

- Noise requirement: if the robot runs in a lab or clean space.

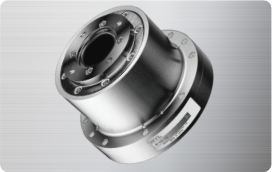

(2) Main motors used

| Model name | Product name | Remarks | |

| 1 | MDH-2018-36KE(end effector) | Ultra-compact hollow-shaft direct drive motor | Outer diameter: φ21 mm, hollow bore: φ2.6 mm Resolution: 144,000 counts/rev Peak torque: 130 mNm |

| 2 | MDH(12)-4018-324KE(middle) | Compact large-bore hollow-shaft direct drive motor | Outer diameter: φ40 mm, hollow bore: φ12 mm Resolution: 1,296,000 counts/rev Peak torque: 1 Nm |

| 3 | MDH-7018-648KE(base) | Compact large-bore hollow-shaft direct drive motor | Outer diameter: φ70 mm, hollow bore: φ25 mm Resolution: 2,592,000 counts/rev Peak torque: 3 Nm |

Notes

Repeatability depends on the full system, including arm stiffness, bearing support, and control tuning. If you share your target cycle and payload, we can recommend a motor set and basic layout.

Contact

Send us your payload, reach, cycle time, and required repeatability. If you need hollow shaft routing for cables or air lines, include that too. We will recommend a suitable μDD motor set for your robot.