Customization Case: Black Anodized Hollow Shaft

Customization Case: Black Anodized Hollow Shaft

This case introduces a black anodized hollow shaft option for μDD motors. It is used when internal reflections inside the shaft cause measurement errors in optical systems.

Overview

We can change the μDD motor hollow shaft to black anodized

Photo shows a black anodized shaft for the MDH(12)-4006.

Problem

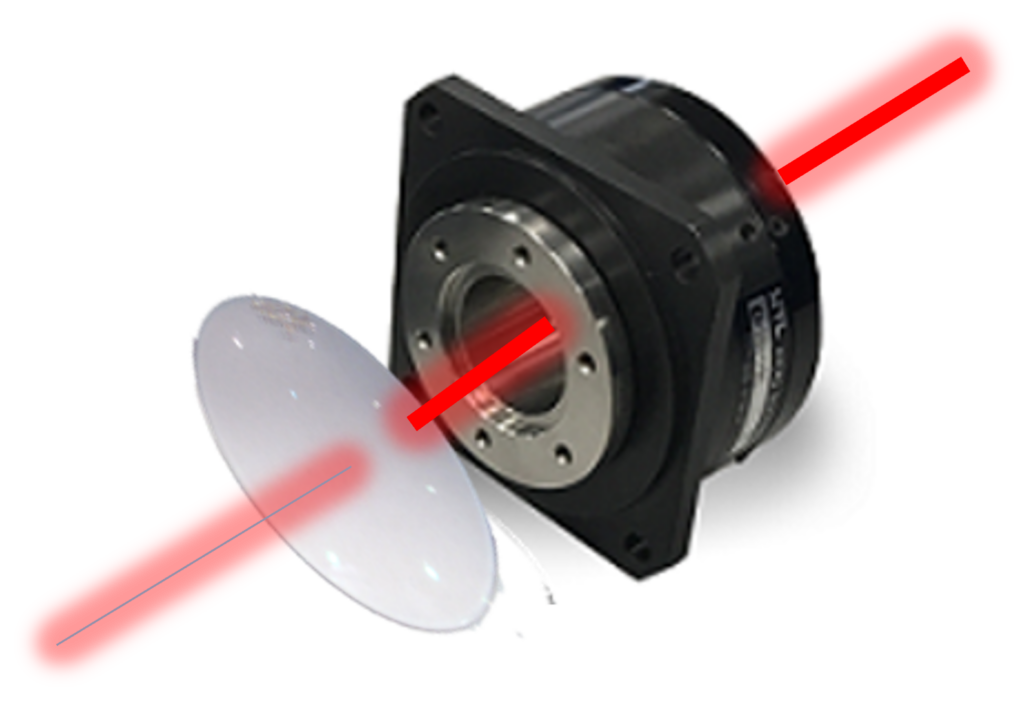

In wavelength inspection of laser light, the laser is passed through the motor shaft and a wave plate is mounted on the motor end face to extract a desired wavelength component. In this setup, a silver inner wall surface reflects the laser light and the measurement becomes unstable.

Customization

To reduce internal reflections, we change the motor shaft material to aluminum and apply a black anodized finish. This suppresses reflection inside the hollow shaft and improves measurement stability.

Tradeoffs

Important: Compared with the standard SUS shaft, allowable load capacity decreases with an aluminum shaft. Check your load conditions before selecting this option.

Applications

This customization is effective for wavelength component measurement and other laser optical modules where reflections inside the hollow shaft cause problems. It is also useful in laser beam conditioning or wavelength conversion equipment.

Contact

Tell us your motor model, shaft inner diameter, laser wavelength range, and the parts you mount on the end face. If you have a drawing of the optical layout, share it. We will confirm the shaft material, surface treatment, and load limits for your setup.