Customization Case: Flangeless Housing

Customization Case: Flangeless Housing

This case introduces a flangeless option for μDD motors. We machine the standard square flange into a round outer profile, or remove the flange entirely, to fit tight installation spaces.

Challenge

Standard μDD motors use a square flange. In tight spaces, such as a robot arm elbow, the flange corners can stick out past the arm outer profile. This becomes a packaging problem and can limit the range of motion or interfere with the intended cover design.

What We Changed

We can make μDD motors flangeless

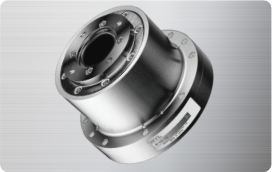

Note: Photo shows a flangeless version of the MDH-7018 (one side only).

We machine the flange area into a round shape that matches the motor outer diameter. This lets the motor sit cleanly inside the arm profile, like it is integrated into the robot arm body.

With the round outer profile, the motor does not protrude from the arm shape. You keep the required motion range and the mechanical design stays clean.

This customization is also effective for other tight mounting areas, especially cylindrical mounting pockets.

Why It Helps

| Issue in the design | What the flangeless shape solves |

|---|---|

| Flange corners stick out of the arm outer profile | Round profile keeps the motor inside the intended outer diameter. |

| Limited space at joints | Cleaner packaging in elbow and wrist areas. |

| Cover and cable routing conflicts | More freedom for housing shape and internal routing. |

Options

We can also make μDD motors cylindrical

Note: Photo shows the MDH-4018.

We can also remove the flange completely. In that case, the motor is mounted using tapped holes machined on the motor side surface.

Design Notes

- Mounting method: confirm whether you want a round flange profile or a fully flangeless side mount.

- Reference surfaces: confirm how you locate the motor in the housing and how you control concentricity.

- Clearances: confirm the arm cover thickness and any interference around the joint.

- Service access: confirm how the motor is installed and removed during maintenance.

Contact

Send us your motor model, target outer diameter limit, and a simple drawing of the mounting space. If you have a robot joint layout, include the interference areas around the elbow or wrist. We will propose a flangeless shape and mounting method that matches your housing.