Customization Case: Larger Hollow Bore

This case introduces a hollow bore size change for the MDH-30 Series. We expanded the standard inner diameter from φ4 mm to φ6 mm to make routing and part integration easier.

Overview

Larger hollow bore

Customization for the MDH-30 Series, inner diameter φ4 to φ6.

Why We Changed It

The MDH-30 Series hollow bore has been φ4 mm as standard. Many rotary joints, air tubes, and ball screws commonly used in compact units are based on φ5 mm class parts. To support those layouts, we expanded the hollow bore so customers can mount and route parts more easily.

Scope

- Target product: MDH-30 Series

- Standard inner diameter: φ4 mm, customized inner diameter: φ6 mm (+2 mm)

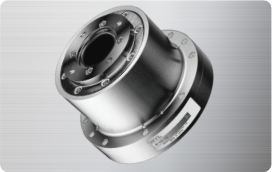

Photo example: MDH(6)-3006

Compared with the standard model, the hollow bore is 2 mm larger.

Result

Increasing the hollow bore gives you more freedom for what you pass through the axis, such as cables, tubes, and small shafts.

It also simplifies wiring and piping layout during machine design, especially when space is tight.

This change helps reduce the overall footprint of the unit and improves service access during maintenance.

Production Status

Hollow bore customization from a dedicated manufacturer

The ratio of inner diameter to outer diameter is sometimes called the hollow ratio. μDD motors are designed with a large hollow bore for their size, typically 20 to 35 percent. This makes bore customization practical when you have a clear routing requirement.

If the standard bore is not enough, if you want a slightly larger bore, or if you already know what must pass through the axis, we can adjust the hollow bore to match your application.

Mass production preparation:

MDH(6)-30 is currently in preparation for mass production. If you are considering this option, contact us early so we can review your specifications and layout during the design stage.

For hollow bore changes

The MDH-30 (φ6) shown here is one example. We also support bore expansion or reduction for other motor sizes, and inner bore design for your use case, including internal tapping. Contact us with your target bore size and what you need to route through the axis.