Customization Case: Pinion Gear Output Shaft

Customization Case: Pinion Gear Output Shaft

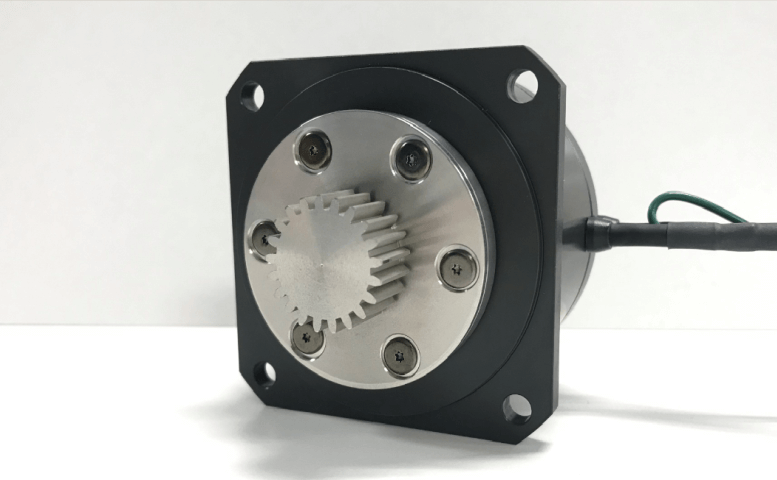

This case introduces an output shaft customization option for μDD motors. We can machine a pinion gear directly on the motor output, or make a special shaft shape, so the motor fits your unit design without extra adapters.

Overview

We can change the μDD motor output shaft shape

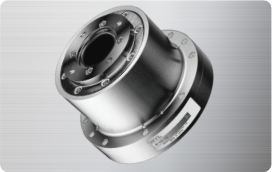

Images show, from left, the MD-40 and MD-70.

What We Can Do

Based on your request, we can supply the motor with an output shaft that includes a pinion gear, or with a special shaft shape. This supports direct engagement with a gear or rack and reduces the need for extra machining or adapter design after delivery.

Why It Helps

| Common issue | What this customization changes |

|---|---|

| Extra machining after delivery | We finish the output form before shipment. |

| Adapter and hub design takes time | Direct gear or rack engagement reduces the parts count. |

| Alignment and runout issues from stacked parts | One-piece output form helps reduce tolerance stack. |

| Assembly time increases | Pre-finished output supports faster, repeatable assembly. |

Typical Specs to Define

- Pinion tooth count and module: define gear spec and mating rack or gear details.

- Material and heat treatment: define wear life requirements.

- Keyway: required or not, and key size if used.

- Gear face width: match load and contact requirements.

- Output length and reference surfaces: define how you locate and support the shaft.

Design Notes

For gear engagement, confirm the radial load, moment load, and expected duty cycle. If your unit uses a rack, share the rack drawing so we can review module, pitch, and alignment assumptions.

Direct drive is backlash free inside the motor, but gear or rack engagement still depends on mesh setup. Plan the mounting stiffness and alignment method early. It prevents rework later.

Contact

Send us your motor model, target pinion gear spec (module and tooth count), material preference, and whether you need a keyway. If you have the mating rack or gear drawing, include it. We will review feasibility and propose an output design for your unit.