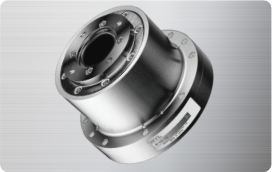

Customization Case: Rotary Joint in Hollow Shaft

Customization Case: Tapped Thread Inside Hollow Shaft

This case shows a simple customization for μDD motors. We cut an internal M5 × 0.8 thread inside the hollow shaft so a rotary joint can be mounted directly without an intermediate adapter.

Overview

Internal tapping inside the μDD motor hollow shaft

What We Changed

We cut an internal M5 × 0.8 thread inside the hollow shaft. This lets you connect a rotary joint directly to the motor without using an intermediate adapter part.

In the example shown, the motor is fitted with a PISCO rotary joint “RL4-M5.”

PISCO rotary joint “RL4-M5”

Why It Helps

With the rotary joint mounted inside the hollow shaft, you can pass cables or air tubing through the axis without the joint touching the hollow shaft end face. This keeps the routing clean and protects the end face from unnecessary contact.

This approach helps reduce the footprint of a Zθ unit in pick and place stations, where height and routing space are tight.

Design Notes

- Thread depth: confirm enough engagement for the rotary joint length and expected load.

- Routing check: confirm tube outer diameter, bend radius, and strain relief through the bore.

- Sealing: if you run air, confirm leak requirements and seal method at the joint.

- Serviceability: plan how the joint is installed and removed during maintenance.

Other Options

We also support combined customizations. For example, we can increase the hollow bore size and add internal tapping as a set when your routing needs more space.

Contact

Tell us your motor model, target bore size, and what you need to route through the axis. If you already selected a rotary joint, share the model and drawings. We will confirm thread spec, engagement, and layout notes for your unit.