MagLinkage Robotics Actuators

MagLinkage is a compact, low-friction actuator concept for fast grasping and controlled motion. This page shows how μDD motors support compact robot hand designs.

User: The University of Tokyo, Ishikawa Group / Osaka University, Harada Laboratory

Developer website: https://kk-hs-sa.website/index.html

1) μDD Motor Benefits

(1) Shock absorption and fast grasping

Grasps objects at high speed while absorbing impact. This helps handle fragile objects safely.

(2) High-accuracy position control

Using ultra-compact direct drive motors enables precise torque control and high resolution. This supports motions that are difficult with many conventional robot hands.

(3) Wider use for robot hands

Fewer wear parts support longer life and lower maintenance. The lightweight, compact design also makes it easier to apply across different robot systems.

This system supports drive performance that was difficult to achieve with conventional robots and expands options in robotics and automation.

Motor Selection

For compact robot hands, motor selection usually depends on grasp force, speed, resolution, and size limits.

- Grasp force and speed: target grip force and open/close time.

- Resolution: how fine the motion must be for stable grasping.

- Size and weight: motor diameter and total hand mass limits.

- Duty cycle: expected operating hours and temperature rise.

2) Main motors used

| Model name | Product name | Remarks | |

| 1 | MDS-1318-11B(Axis 1) | Ultra-compact direct drive motor | Outer diameter: φ13 mm Resolution: 2,048 counts/rev Peak torque: 24 mNm |

| 2 | MDS-2018-36KE(Axes 2 and 3) | Ultra-compact direct drive motor | Outer diameter: φ21 mm Resolution: 144,000 counts/rev Peak torque: 130 mNm |

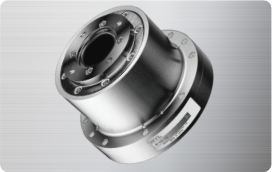

| 3 | μDD Motor with gear | Compact large-bore hollow-shaft direct drive motor | Outer diameter: φ70 mm, hollow bore: φ25 mm Resolution: 2,592,000 counts/rev Peak torque: 3 Nm |

Reference

Developer website: https://kk-hs-sa.website/index.html

Contact

Send us your target grasp force, speed, size limit, and duty cycle. We will recommend a suitable μDD motor and share integration notes for your hand or end-effector.