Real Haptics Prosthetic Hand

This case shows a prosthetic hand that transfers force and touch information to another body part. The goal is better control for delicate tasks by improving backdrivability.

Restore force and touch feedback for more natural control.

User: Keio University, Nozaki Laboratory

Nozaki Laboratory website: http://www.fha.sd.keio.ac.jp/jp/nozaki/nozaki.html

Challenge

Many prosthetic hands do not provide contact sensation. Without feedback, users cannot adjust grip force well, and delicate tasks become difficult.

This research targets a clear requirement: transfer force and touch information from the hand to another body part, in real time, so the user can control grip more naturally.

μDD Motor Benefits

To feel force and touch realistically, the mechanism needs good backdrivability. One direct approach is to reduce the reduction mechanism as much as possible.

By using a high-torque μDD motor and lowering the gear reduction ratio, the system achieved good backdrivability while keeping the actuator compact.

Motor Selection

For haptics and backdrivable mechanisms, motor selection usually starts from these checks.

- Backdrivability target: how easily the joint should move when external force is applied.

- Torque margin: peak torque for fast motion and stable control.

- Reduction ratio: lower ratios support backdrivability but require more motor torque.

- Resolution: feedback resolution needed for stable force control.

- Size and weight: limits for prosthetic hand integration.

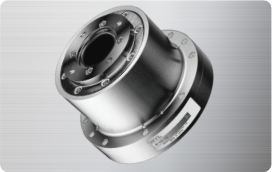

Motor Used

| Model name | Product name | Remarks | |

| 1 | MDS-2018-9000E with gear | Hollow low-reduction geared μDD motor | Outer diameter: φ21 mm Resolution: 36,000 counts/rev Peak torque: 0.84 Nm |

Integration Notes

- Start from the reduction ratio: it sets backdrivability and required torque.

- Check friction sources: bearings, seals, and cable routing often dominate feel.

- Confirm force control stability: validate with real interaction, not only position tests.

- Thermal check: continuous force feedback can raise motor temperature.

Contact

Send us your joint torque target, backdrivability requirement, size limit, and duty cycle. We will recommend a suitable μDD motor and a practical reduction approach for haptics applications.